Processing Service

Nano Alloy has a million-class clean workshop, adopting a one-stop production model from smelting and molding to component processing, thereby achieving meticulous quality management and efficient production development.

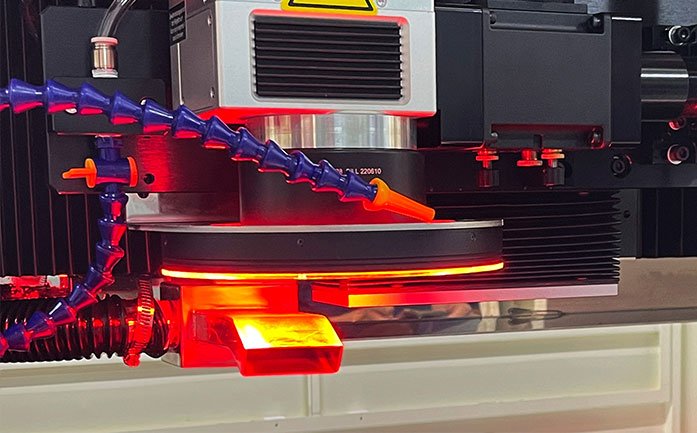

Cutting

High-precision femtosecond laser precision processing equipment uses imported femtosecond laser heads for non-carbonized precision tubular or flat cutting to avoid product burrs, black edges, micro cracks, etc. The cutting accuracy can reach micron level, and is widely used in the manufacturing of medical implant products, such as the processing of tiny and fine parts such as developer rings and electrode sheets.

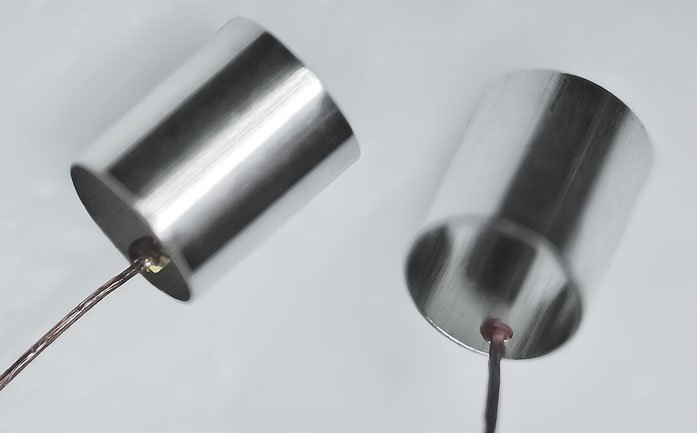

WELDING

Equipped with high-precision laser welding, resistance welding, argon arc welding, vacuum brazing and soldering equipment, equipped with precise visual positioning and monitoring systems, with fast welding speed, small thermal deformation, small welding spot, and the smallest welding point can be as small as 0.05mm. Customized processing is supported, and there is no limit on raw materials.

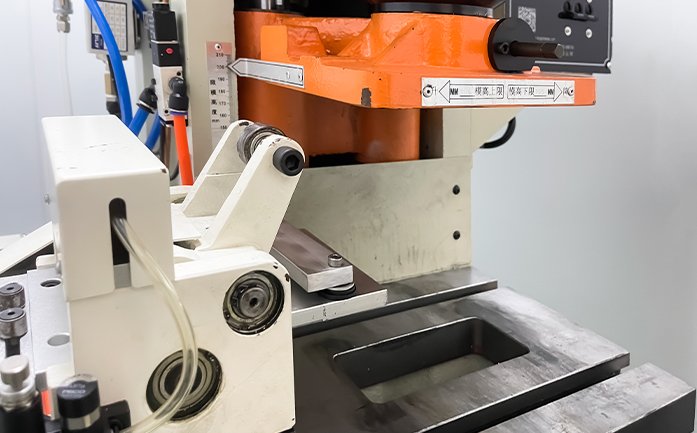

STAMPING

The stamping production line has high-quality precision and high-efficiency speed. The technical parameters are strictly controlled throughout the production process to ensure minimum loss and qualified rate of finished products. Our daily output can reach 60,000 PCS, fully demonstrating the production capacity and stability of the production line.